Stainless Steel Single Wire Braided Corrugated Flexible Metal Hose/Pipe with Fitting for Construction

Basic Info

| Model NO. | 300 series |

| Cross-Section Shape | Round |

| Connection Type | Flange |

| Name | Stainless Steel Single Braid Flexible Metal Hose |

| Sample | Available |

| Hose Type | Omega/U-Type |

| Max Working Pressure | 40MPa |

| Optional | Fitting/Flange/Braid |

| Material Grade | Stainles Steel 304/316/316L/321 |

| Testing | Hydro Testing / Pneumatic Testing |

| Lead Time | 7 Days |

| Payment | T/T |

| Braiding Layer | 1/2/3 |

| Hose Length | 100 Meters Per Coil |

| Working Pressure | Customized |

| Thickness | 1-12mm |

| Package | Seaworthy Package |

| Usage | Hydraulic/Automobile Pipe, Oil/Gas Drilling |

| Transport Package | Standard Seaworthy & Strong Package |

| Specification | ISO9001 |

| Trademark | Comflex |

| Origin | Jiangsu, China |

| HS Code | 73079900 |

| Production Capacity | as Requested |

Product Description

Stainless Steel Single Wire Braided Corrugated Flexible Metal Hose/Pipe with Fitting for Construction

What is a flexible metal hose?

- Corrugated hoses are absolutely leak-tight and are used to convey liquids or gases under pressure or as vacuum lines. They are also referred to as pressure hoses. Their special design achieves both flexibility and pressure resistance.

Where can you use a flexible hose?- Types, Benefits, and UsesFlexible hoses are used for transferring fluids including liquids like chemicals, oils, and water, and gases fluids like gases, steam, and air. They function for the absorption of thermal expansion, centering and vibration of piping, and for reciprocation of piping systemsWhat are the advantages of flexible hoses?- The benefits of the flexible hose over rigid pipe and tubing are that the flexible hose is simple to route, withstands vibration and thermal expansion or contraction

| Product name | Stainless Steel Single Braid Flexible Metal Hose/Pipe with Fitting |

| Material | Stainless Steel 304, 321, 316 and 316L |

| DN | 6-300mm |

| Hose Type | Annular corrugated |

| Application | Water, gas, industrial, steam, chemical |

| Braided Mesh | Single / Double layer |

| Connect Type | Flange/Thread/Quick coupling |

| Connector approval | Loose or fixed flange |

| Braided mesh layer | single or double-layer braiding |

------Technical Data

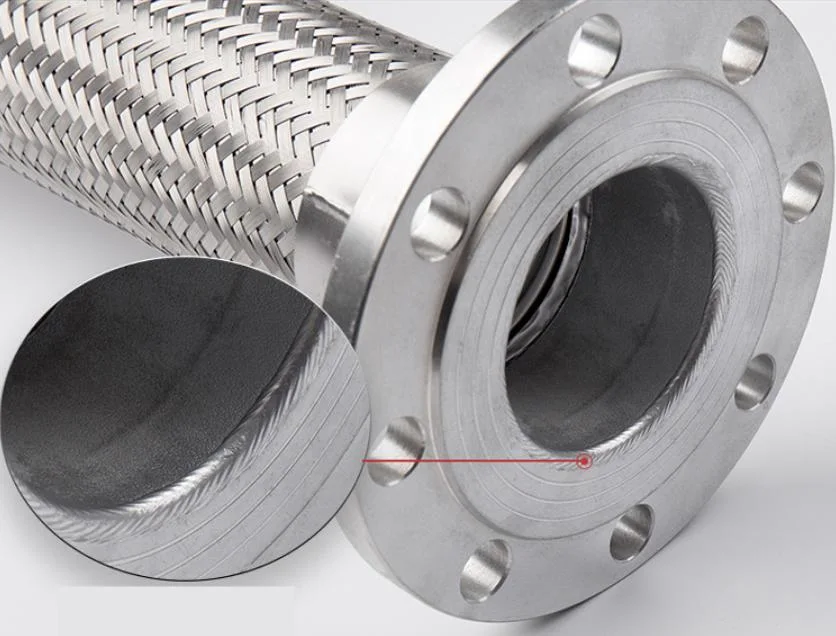

Construction of Flexible Metal Hose

Inner Core: Corrugated Stainless Steel

•Flexible metal hose stainless steel core strengths are available in 304, 321 and 316L stainless steel

•Stainless steel tubing formed into corrugations parallel to one another

•Helical / Convoluted option available upon request

Outer Core: Braided Stainless Steel Layers

• Purchase corrugated core hose with no layers, single or double braided

•Flexible metal hose outer braid layers made from 304 stainless steel

•See braid layer code key at the bottom of this table

Benefits of Flexible Metal Hose

•All metal hose - corrugated stainless steel core, sold standalone or with braided steel layers

•Pressure tolerances include full vacuum to those listed in the spec table below

•Application Temperature ratings from Cryogenic to 1500° F

•Meets or exceeds ISO 10380 at the maximum working pressure

Braids

Metal wire braid on a hose assembly provides the hose assembly a higher pressure capability by acting as a restraint against hose elongation and acts to dampen vibration. The second layer of braid may be used to increase pressure ratings provided the test pressure is not exceeded.

Applications:

This hose is suitable for conveying all types of liquid and gases with extremely low and high-temperature requirements. Corrugated Stainless Steel Braided Pressure Hose, to ISO 10380 specification.

| Standard Flexibility hoses | |||||||||||||||

| DN | Corrugated hoses | Braid | Single Braid | Double Braid | |||||||||||

| ID | OD | Pitch Distance | Thickness | No. of Carrier | No. of wiresin carrier | Wire Dia. | Dia of Hose withSingle Layer of braiding | Working Press. | Test Press. | Working Press. | Test Press. | ||||

| I. D.(mm) | Devi.(mm) | O. D.(mm) | Devi.(mm) | I(mm) | Devi.(mm) | S(mm) | NC | NW | WD(mm) | OD(mm) | Bar | Bar | Bar | Bar | |

| 8 | 8 | ± 0.10 | 12.3 | ± 0.10 | 2.9± 0.2 | ± 0.02 | 0.2 | 36 | 4 | 0.3 | 14.5 | 80 | 120 | 140 | 210 |

| 10 | 10 | ± 0.10 | 14.6 | ± 0.10 | 2.8 | ± 0.01 | 0.2 | 36 | 5 | 0.3 | 15.8 | 90 | 135 | 140 | 200 |

| 12 | 12 | ± 0.10 | 18 | ± 0.10 | 2.8 | ± 0.02 | 0.2 | 36 | 6 | 0.3 | 19.2 | 80 | 125 | 120 | 180 |

| 15 | 14.4 | ± 0.10 | 21.5 | ± 0.10 | 3.5 | ± 1 | 0.3 | 36 | 6 | 0.3 | 22.1 | 80 | 125 | 120 | 180 |

| 20 | 20 | ± 0.10 | 27 | ± 0.10 | 4.5 | ± 1 | 0.28 | 36 | 9 | 0.3 | 29.2 | 60 | 90 | 80 | 100 |

| 25 | 25 | ± 0.10 | 32.5 | ± 0.10 | 5 | ± 1 | 0.28 | 36 | 10 | 0.3 | 33.7 | 60 | 90 | 80 | 100 |

| 32 | 32 | ± 0.10 | 40 | ± 0.10 | 5 | ± 1 | 0.28 | 36 | 11 | 0.3 | 41.2 | 50 | 80 | 70 | 90 |

| 40 | 40 | ± 0.10 | 50 | ± 0.10 | 6 | ± 1 | 0.28 | 36 | 11 | 0.3 | 51.2 | 50 | 80 | 70 | 90 |

| 50 | 50 | ± 0.10 | 63 | ± 0.10 | 6 | ± 1 | 0.3 | 48 | 12 | 0.4 | 64.6 | 40 | 70 | 60 | 80 |

| 65 | 65 | ± 0.10 | 81 | ± 0.10 | 7 | ± 1 | 0.4 | 64 | 1 | 0.4 | 82.6 | 40 | 70 | 60 | 80 |

| 80 | 80 | ± 0.10 | 98 | ± 0.10 | 10 | ± 1 | 0.4 | 64 | 15 | 0.4 | 99.6 | 30 | 60 | 50 | 70 |

| 100 | 100 | ± 0.10 | 120 | ± 0.10 | 11.5 | ± 1 | 0.4 | 96 | 12 | 0.4 | 121.6 | 16 | 30 | 30 | 50 |

| 125 | 125 | ± 0.10 | 150 | ± 0.10 | 13 | ± 1 | 0.5 | 96 | 12 | 0.5 | 151.6 | 16 | 30 | 30 | 50 |

| 150 | 150 | ± 0.10 | 180 | ± 0.10 | 14 | ± 1 | 0.5 | 96 | 14 | 0.5 | 181.6 | 16 | 30 | 30 | 50 |

| 200 | 200 | ± 0.10 | 230 | ± 0.10 | 17 | ± 1 | 0.6 | 120 | 16 | 0.5 | 232 | 16 | 30 | 30 | 50 |

| 250 | 250 | ± 0.10 | 280 | ± 0.10 | 27 | ± 1 | 0.8 | 140 | 18 | 0.5 | 282 | 10 | 20 | 20 | 40 |

| 300 | 300 | ± 0.10 | 340 | ± 0.10 | 28 | ± 1 | 0.8 | 144 | 18 | 0.5 | 342 | 8 | 16 | 16 | 30 |

------Various connectorVarious connectors can be welded or clamped onto the metal hose for different applications

------Detail displayUniform braiding without pin hole, to ensure the anti-explosion performance

Movable flange joint, to connect with the pipe system perfectly

Bright welding joint to ensure the hose quality

------Hose TestingBefore delivering the goods, we will test the hose by leakage testing and hydro-testing to ensure the hose complies with its requirement.

------Certifications

------Standard seaworthy package

We adopt standard seaworthy package for all export orders.

Flexible metal hose container package

------WHO WE ARE

Comflex Industrial

We make all kinds of flex-related products, such as flexible metal hoses, expansion joints, braidings, hose fittings, and related machines, such as elastomer hose forming machine, hydraulic forming machine, wire braiding machine, rewinding machine, bellow forming machine, etc..We are lead manufacturer of flex-related products in China.We supply metal hose and braid with the widest selection of products ranging from the braided hose for value-oriented customers to super flexible hoses to ultra-high pressure and high-temperature hoses that satisfy the industry's most demanding applications. Working closely with customers and suppliers helps us build quality products that meet or exceed compatibility and functional requirements, safety, and environmental standards and deliver dependable, repeatable performance and value.

------Manufacturing facilities

A: Tube welding machine (DN12-300)

B: Hydraulic forming metal hose making machine - U type hose (DN32-300)

C: Mechanical hose making machine - U type hose (DN6-40)

D: Elastomer (PU) hose-making machine - Omega type hose (12-100)

E: Wire braiding machine (24 carriers - 156 carriers)

------FAQ

Q: Why so many suppliers choose us?

A: Because we are one of the most professional manufacturers of the metal hose with more than 25 years of experience

Q: What sizes can you make?

A: all sizes from DN6 up to DN300

Q: What kind of fittings can you supply with the metal hose?

A: nuts, adapter, nipple, with BSP or NPT thread, we can customize our hose according to your requirement

We need to know the following information to give you our best quotation for the hoses:

A: Material of the hose:sus304,321,316 or 316LB: Material of the fittings, are they flange or pipe ends? Flange code?C: Length and DiameterD: Working pressure and temperature of the hose